Offline CNC Processing Center

MAC glass processing center CNC is an all-in-one machine. It can help you with all different glass processing including cutting, drilling, milling, notching, engraving, inner/outer/shape grinding and polishing etc.

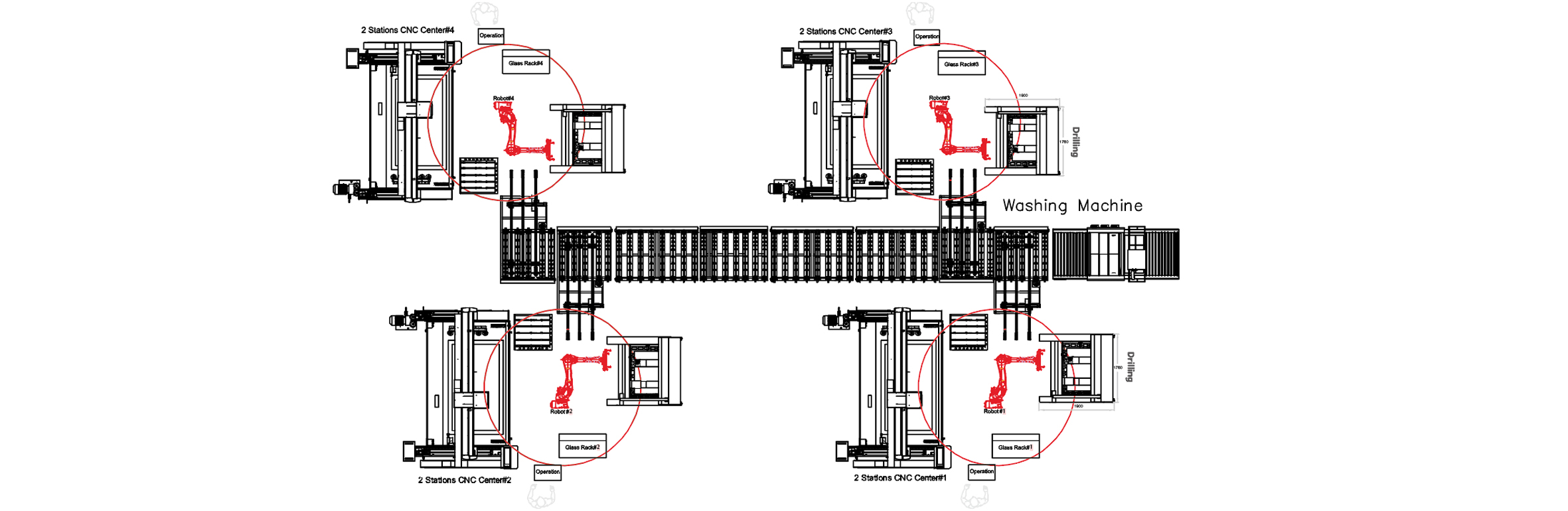

All MAC different processing center solutions can work online integrated with MAC software. It serves your architectural glass, appliance glass, automotive glass and electronic glass processing with a perfect full line solution.

Glass processing including:Cutting,Drilling,Milling,Notching,Inner(outer) shape Grinding and Polishing.

Gantry design composed of 4-axis control x-axis, y1-axis, y2-axis and z-axis; It is convenient to operate the upper and lower pieces of glass;

The gantry bridge is driven by two servo motors y and Y1, and is also equipped with two ball screws and linear guide rails;

Double table and double station processing can be set. For the glass with small size, it is positioned in two pieces. The machine head automatically selects to grind the glass in one station and automatically process the glass in the second station;

It can be used for glass edge grinding (straight edge / round edge / duck beak edge, etc.), polishing and other processing processes;

The plug-in quick vacuum suction cup connector is located in front of the workbench, which is convenient to adjust and replace the suction cup position;

The double-sided vacuum suction cup fixing system can quickly and simply locate the glass;

Mechanical Structure:

The whole machine is welded into a stable steel structure by a group of high- strength steel. The structure has a very stable base to form a stable support structure. After annealing, all processing surfaces of the whole machine are processed and formed as a whole.

High strength gantry beam is an important mechanical component; And through multiple internal stress elimination treatment to ensure that the whole beam does not deform;

The whole table is made of a whole piece of aluminum material, and the aluminum plate is finely ground to ensure the flatness and machining accuracy of the suction cup on the table;

The specially designed positioner adopts double lifting cylinder design to ensure good positioning accuracy and positioning height;

The quick plug vacuum suction cup connector is located in front of the workbench to facilitate the disassembly and assembly of the suction cup / positioner;

The professionally designed suction cup can more stably absorb the glass without scratching;

High power and high-speed spindle can better ensure the concentricity and machining accuracy of grinding wheel; The maximum speed of high-speed spindle is 12000 rpm, and the grinding wheel parameters can be easily set through software;

CNC System:

The equipment operation is controlled by professional CNC system to ensure the stable operation of the equipment;

The operation interface runs under windows through an industrial computer. It only needs to complete some simple interactive operations, which is very intuitive and concise;

The editing of graphics can be carried out directly on the computer through the CAD graphics for simple tool matching and processing;

Application:

Architectural Glass

Appliance Glass

Automotive Glass

Electronic Glass

Automatically check whether the processing procedure is feasible

Automatically adjust the working speed according to different processing arc radius

The polishing wheel loss is automatically adjusted by the pressure sensing system to ensure the polishing effect

To find out more information about any of The services or products

Get in touch