This type of automatic loading/unloading system is commonly used at edging, drilling and other pre-processing stations. It is characterized by its high speed, flexibility and reliability. The whole machine consists positioning conveyor, moving arm and suckers, HMI and PLC control system.

According to the whole line design, the glass stacking location can be straight or 90 degree with the line. As different processing request, the stacking stations can be single or multiple. It is effective accessories for full line automation.

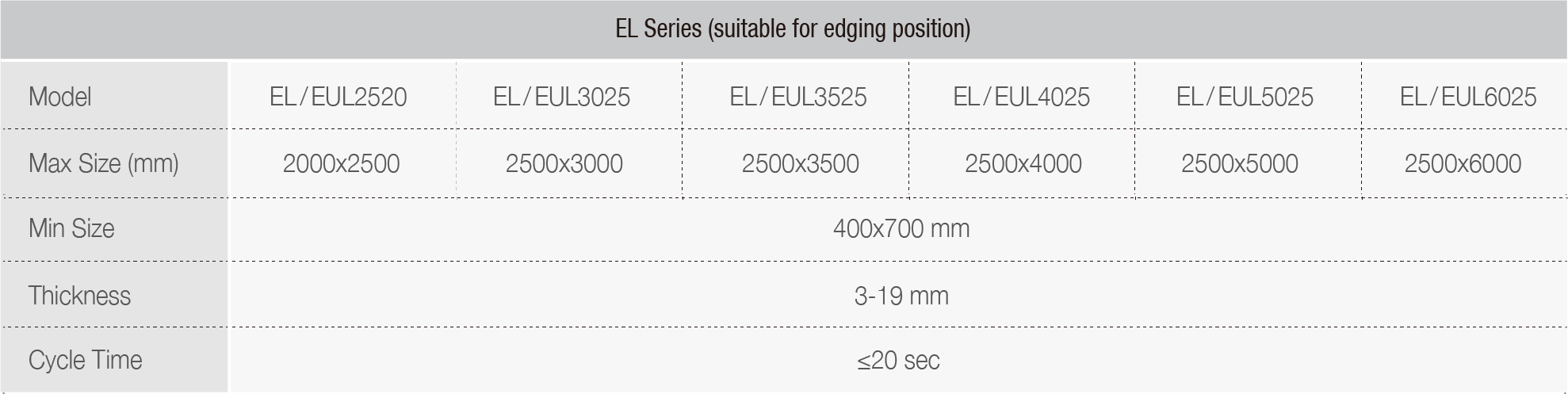

The loading and unloading tables use servo motor as drive system and all motors with infinitely variable speeds, the transfer speed is 2- 35m/min; Loading & Unloading cycle time is around 20-40S.

Adopts full-closed loop control system for accurate positioning for the machine and stable running system.

4 axis all-digital control with precise positioning and speedy flexibility; All speed can be adjustable according to production line speed.

Super HMI monitor the equipment running status and system parameters; It can set data according to different glass rack height and angle and also pre-setting or recording the current shift of production.

Vacuum pump system: highly effective mono-block rotary blade type vacuum pump.

The automatic loading & unloading table Y axis use Servo motor, the transfer and the suction cup tilting arm using high class motors with inverter as drive source; Which will ensure smooth running and jitter-free.

Precise positioning and speedy flexibility.

Each sucker can be controlled individually.

Freely connect with double edging machine & washing machine.

To find out more information about any of The services or products

Get in touch