From October 22 to 25, 2024, the glasstec trade fair was successfully held in Düsseldorf, Germany,

bringing together glass processing companies, glass machinery manufacturers, and top distributors/agents from dozens of countries worldwide.

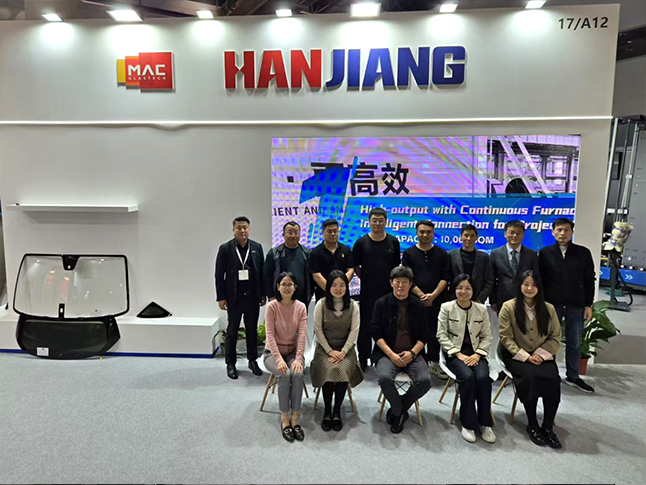

This event also marked MAC's debut in Düsseldorf.

The deep glass processing industry is undergoing a significant transformation:

from disorder to order, from passive processing to proactive management, and from risk to safety.

This evolution has led to improved product quality control, optimized efficiency, reduced energy consumption and labor involvement,

enhanced production management and upgraded safety in production.

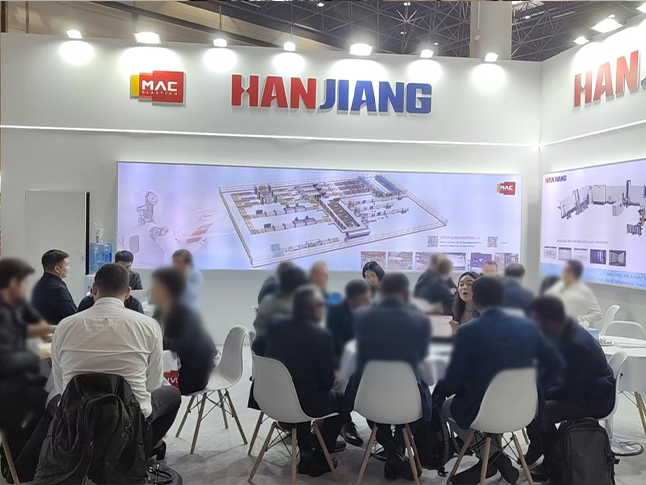

At the exhibition, we discussed intelligent production for glass processing with customers, distributors, and agents,

and explored how MAC empowers smart glass factories.

Topics of discussion included:

1/ Management upgrading- transitioning from traditional extensive management to one that bases investment on market analysis,

analyzes capacity according to order structure, determines pricing based on actual losses, and optimizes capacity through lean processes to reduce costs.

2/ Automation upgrading- where optimizing factory logistics and achieving efficient automation and intelligence significantly improve product quality and reduce labor’s involvement.

Intelligent raw glass storage system, intermediate product storage system, and finished product storage system.

Intelligent marking system and identification system.

Intelligent furnace batching system.

Intelligent sorting and pairing system.

Automated conveying mechanism.

3/ Functional machines upgrading. Truly intelligent machines represent the ultimate challenge for a smart factory,

requiring an in-depth analysis of processes and absolute control over production.

Fully automatic edging and pre-processing equipment upgrades

Intelligent tempering furnace

Fully automated smart insulating glass production modules

4/A factory-wide ERP+MES system can effectively manage each processing equipment,

optimize orders, and decompose them into independent equipment instructions, processing them in a language the equipment can understand.

By extracting production data from the ERP+MES system,

calculating the effective capacity of each individual equipment and the actual cost of each order becomes much easier.

Whether you are involved in architectural glass, shower doors, appliance glass,

automotive glass, or photovoltaic glass, we can provide tailored solutions for you.

This is all made possible by our powerful software system that integrates each functional device.

The MAC team is ready to offer you even more comprehensive solutions in the future.

The themes discussed resonated strongly and attracted significant attention from industry professionals.

We firmly believe that MAC’s glass processing solutions are practical and grounded in extensive R&D and manufacturing experience,

continuously delivering quality service to the market.

We extend our gratitude to our clients, agents, distributors, and industry peers for their support,

and look forward to gathering again in Germany in 2026.